Our Work

Project Description

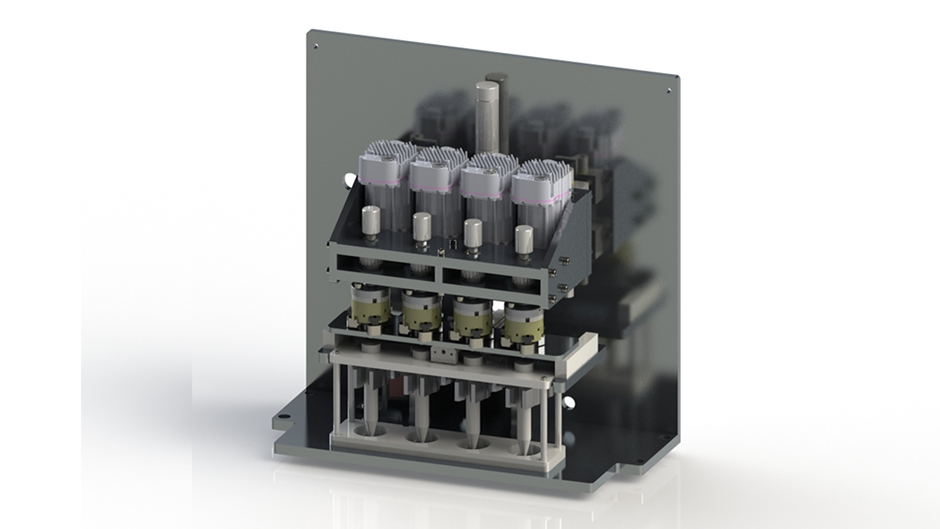

A larger system required a rack-based capper/decapper for 15 ml Falcon tubes. To facilitate process workflow, two different racks of tubes needed to be capped/and decapped. Intense Engineering designed and built a single capper/decapper that could accommodate both racks. After the first rack of tubes are decapped, caps are placed onto a retractable shelf. After the second rack of tubes are decapped, caps are held in the gripper; capping is done in reverse order. Torque-controlled servo motors ensure consistent closing. Integrated barcode scanners facilitate sample tracking.